Micro‑OLED displays are much smaller and more advanced than traditional OLEDs, with pixel sizes under 10 micrometers that enable sharper images in compact devices like AR glasses and smartwatches. They’re manufactured using precise processes like photolithography, which makes them more complex and costly. Their higher pixel density provides better clarity and brightness, especially in close-up views. To learn more about how these tiny screens differ across applications, keep exploring the details ahead.

Key Takeaways

- Micro‑OLED features pixels smaller than 10 micrometers, enabling higher pixel density and sharper images for compact devices.

- Micro‑OLED layers are stacked tightly on ultra-thin, flexible substrates, allowing for ultra-thin, lightweight designs.

- Manufacturing micro‑OLED involves advanced photolithography and transfer techniques, making it more complex and costly than traditional OLED production.

- Micro‑OLED provides higher brightness, better contrast, and more vivid colors suited for close-viewing applications like AR and wearables.

- Durability and lifespan of micro‑OLEDs are currently shorter, with ongoing research to improve their longevity compared to larger OLED displays.

Structural Differences Between Micro‑OLED and OLED Displays

Micro‑OLED and OLED displays differ primarily in their structure, which directly impacts their performance and applications. Micro‑OLED displays feature a much smaller pixel size, often less than 10 micrometers, allowing for higher pixel density and sharper images at close viewing distances. Their construction involves stacking the organic layers very tightly, resulting in a compact, ultra-thin profile ideal for small devices like smartwatches and AR glasses. In contrast, OLED displays have larger pixels and thicker layers, making them suitable for larger screens like TVs and smartphones. The key structural difference lies in the size of the active layers and pixel pitch, which influences clarity, power efficiency, and durability. These design variations determine how each display type performs in different environments and devices. Additionally, Vetted – 1st Home Theatre Projector, which emphasizes high-quality display performance, highlights how these structural differences can significantly affect visual experience and device application.

Size and Form Factor Variations

The size and form factor of Micro‑OLED and OLED displays vary considerably, shaping their suitability for different devices and user experiences. Micro‑OLEDs are typically compact, designed for wearables, smart glasses, and small screens, offering high pixel density in tiny packages. In contrast, OLED displays can range from small smartphone screens to large TVs, providing flexibility for various sizes and shapes. This variation affects device design, weight, and ergonomics. For example:

| Display Type | Typical Size Range | Common Applications |

|---|---|---|

| Micro‑OLED | 0.5″ – 2″ | Smartwatches, AR glasses |

| OLED | 5″ – 85″ | Smartphones, TVs |

| Both | Custom sizes | Automotive, industrial displays |

Device versatility is also influenced by the form factor of each display type, impacting how they integrate into different products.

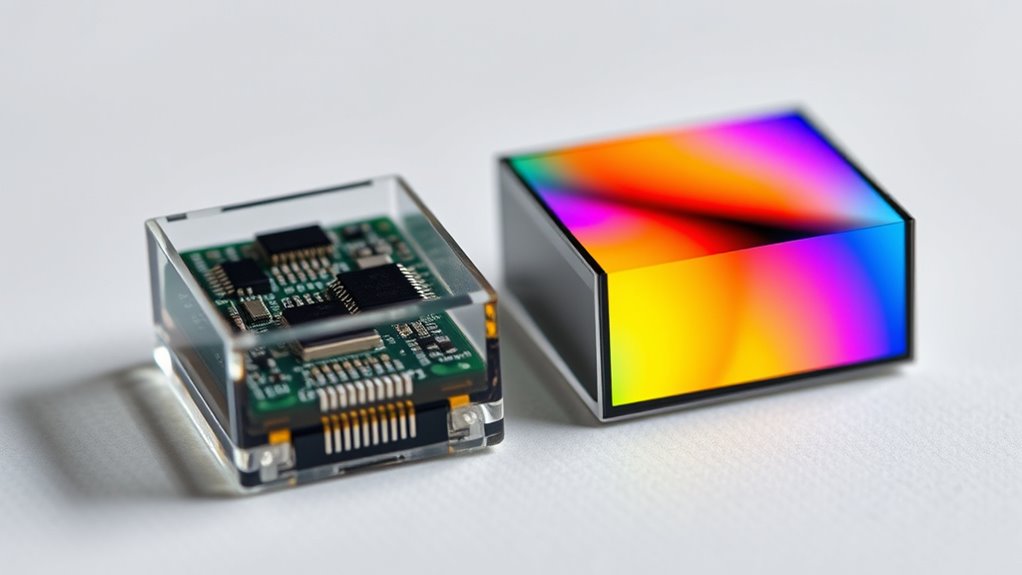

Manufacturing Processes and Materials Used

Manufacturing processes and materials used in Micro‑OLED and OLED displays differ considerably, reflecting their distinct applications and size constraints. Micro‑OLED production involves fabricating extremely small, high-precision components, often using advanced photolithography and transfer techniques to create tiny, high-resolution pixels. These processes demand precision and miniaturization to maintain performance at a small scale. In contrast, OLED manufacturing involves depositing organic layers onto larger substrates through methods like vacuum thermal evaporation or solution processing. The organic materials themselves vary in composition, with Micro‑OLED often utilizing more specialized compounds to optimize size and efficiency. Additionally, Micro‑OLED displays require ultra-thin, flexible substrates to fit into compact devices, while OLEDs may use glass or plastic substrates for larger screens. These differences directly impact production complexity and material choices. Moreover, advancements in automation technologies are increasingly influencing the manufacturing of both display types, enhancing precision and reducing costs.

Pixel Density and Resolution Capabilities

Pixel density varies markedly between Micro-Oled and OLED displays, affecting image sharpness and detail. Higher pixel density generally means crisper visuals, but it can also impact power consumption and manufacturing complexity. Understanding these resolution performance differences helps you choose the right display for your needs. Additionally, display technology plays a crucial role in determining overall performance and longevity.

Pixel Density Variations

While both micro-Oled and OLED displays can achieve high pixel densities, their resolution capabilities often differ considerably. Micro-Oled screens typically pack more pixels into a smaller area, resulting in sharper images and finer details at close viewing distances. This high pixel density allows for a more immersive experience, especially in compact devices like smartwatches or VR headsets. OLED displays, on the other hand, may prioritize larger screen sizes with slightly lower pixel densities, focusing on overall image quality and color accuracy. Variations in pixel density can influence how crisp images appear and how well the display handles detailed graphics. Additionally, the impact of pixel density on user experience is critical in selecting the appropriate display for specific applications. Understanding these differences helps you choose the right display based on your needs, whether for close-up use or larger screens where resolution is less critical.

Resolution Performance Differences

Although both micro-Oled and OLED displays can deliver impressive resolution performance, their resolution capabilities often differ considerably. Micro-Oled screens typically have higher pixel densities due to their smaller size, resulting in sharper images and more detail in compact devices. This allows for crisper text, finer graphics, and a more immersive experience in devices like smartwatches and VR headsets. OLED displays, while offering excellent resolution, generally have larger pixels and lower pixel densities, which can make images appear less sharp when scaled down. However, OLEDs excel in overall color accuracy and contrast, making them ideal for larger screens. Your choice depends on whether you prioritize maximum sharpness and detail or broader color performance in your display. Additionally, pixel density plays a crucial role in overall image clarity and user experience.

Brightness and Power Efficiency

When comparing micro-OLED and OLED displays, brightness and power efficiency are key factors to contemplate. Micro-OLED screens often deliver higher brightness levels, making images pop even in bright environments. This is because their smaller pixels allow for more precise control of light output, resulting in vivid visuals. On the other hand, power efficiency varies depending on usage; micro-OLEDs typically consume less power when displaying darker images due to smaller pixel sizes and lower current requirements. However, maintaining high brightness can increase power consumption. If you need a display that shines brightly without draining your battery quickly, micro-OLED technology offers an advantage. Balancing brightness and maintenance and cleaning is vital for optimizing your device’s performance and battery life.

Contrast Ratios and Color Reproduction

You’ll notice that micro-OLED displays offer enhanced contrast levels, making dark scenes look deeper and more detailed. They also deliver more vibrant color accuracy, so images appear richer and more lifelike. Understanding how these factors impact overall picture quality helps you choose the right display for your needs.

Enhanced Contrast Levels

Enhanced contrast levels are essential for delivering vivid images and deep blacks, making scenes more lifelike and immersive. Higher contrast ratios help distinguish details in dark and bright areas, ensuring clarity and depth. Micro‑OLED displays often feature better contrast due to their ability to turn pixels completely off, producing true blacks. This results in more striking visuals and improved visual comfort. The table below highlights key differences: | Feature | Impact | |————————|—————————————————| | Contrast Ratio | Higher ratios yield deeper blacks and brighter whites | | Pixel Control | Precise control enhances contrast and detail | | Black Levels | Achieve true black, improving overall image depth | Additionally, advancements in display technology contribute to even more impressive contrast performance.

Vibrant Color Accuracy

Building on the improved contrast levels, vibrant color accuracy further enhances the visual experience by delivering more lifelike and rich colors. Micro-OLED displays excel at reproducing a wider color gamut, meaning you see more vivid and true-to-life hues. This results in images that pop with depth and detail, making everything from photos to videos feel more immersive. Unlike traditional OLEDs, Micro-OLEDs often have better color consistency across different viewing angles, so colors stay accurate no matter how you look at the screen. Additionally, their precise pixel control allows for subtle color gradations, reducing banding and enhancing overall clarity. When you combine high contrast with vibrant color reproduction, your visual experience becomes sharper, more dynamic, and more true to life.

Durability and Longevity of the Displays

While both micro-OLED and traditional OLED displays offer impressive visual quality, their durability and longevity can differ markedly. Micro-OLEDs tend to have shorter lifespans due to their smaller size and manufacturing complexities. However, advancements are improving their resilience. Here are key differences to contemplate:

Micro-OLEDs offer stunning visuals but may have shorter lifespans and higher burn-in risks compared to traditional OLEDs.

- Lifespan: Traditional OLEDs typically last around 20,000 to 50,000 hours, while micro-OLEDs can be shorter unless specially engineered.

- Burn-in Risk: Both types face burn-in, but micro-OLEDs are more susceptible because of their higher pixel density.

- Degradation: Organic materials in micro-OLEDs degrade faster, impacting long-term performance.

- Protection: Micro-OLEDs often require additional protective layers to enhance durability, adding complexity to their design.

Additionally, ongoing research aims to improve the durability of micro-OLEDs to match or surpass traditional OLEDs.

Understanding these factors helps you choose the right display for your needs.

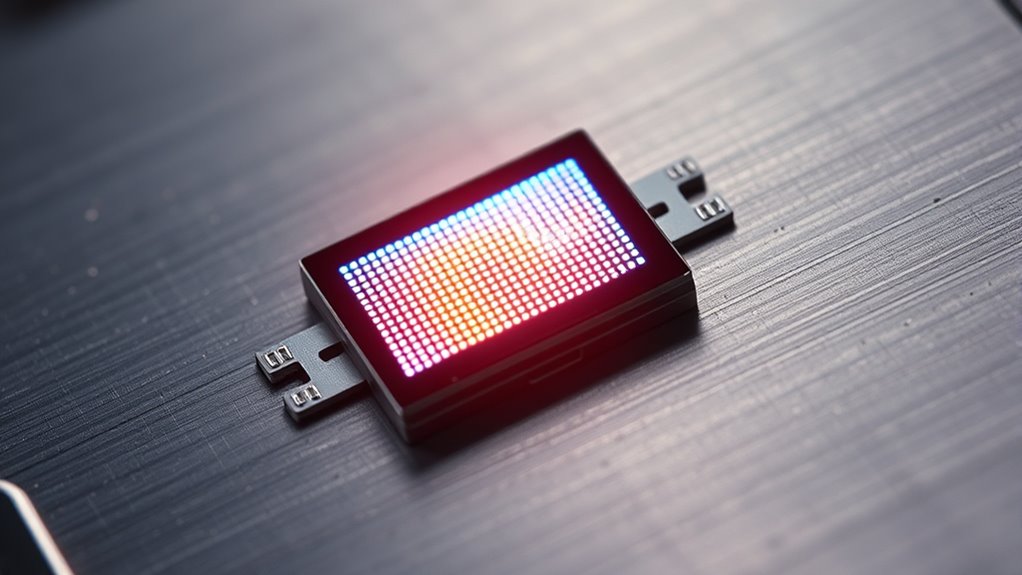

Typical Applications and Use Cases

Your choice between Micro-Oled and OLED depends heavily on device integration, power efficiency, and display quality. Micro-Oleds often excel in compact gadgets, offering flexible designs and lower power draw, while OLEDs provide stunning visuals for larger screens. Understanding these applications helps you select the best display technology for your specific needs. Additionally, considerations like installation guidelines and proper component integration are crucial for optimal performance and safety.

Device Integration Flexibility

Micro-OLED displays offer greater flexibility in device integration compared to traditional OLEDs, making them ideal for compact and specialized applications. Their small size and lightweight design enable seamless incorporation into various devices. Whether you’re developing smart glasses, wearable tech, or augmented reality headsets, micro-OLEDs fit perfectly into tight spaces. Their customizable form factors allow for tailored mounting and connection options. You can also integrate them with various sensors and electronics more easily. Here are some key applications:

- Smart glasses and heads-up displays

- Compact medical devices and wearables

- Augmented reality and virtual reality headsets

- Industrial equipment with space constraints

This flexibility helps you innovate without compromising on performance or design.

Power Consumption Efficiency

Because of their smaller size and advanced manufacturing processes, micro-OLED displays typically consume less power than traditional OLEDs, making them ideal for battery-operated devices. This efficiency extends their usability in applications like smart glasses, head-up displays, and augmented reality devices, where conserving power is vital. When you use a micro-OLED, you’ll notice longer battery life and less frequent recharging, especially during extended use. Their low power consumption also reduces heat generation, which can improve device comfort and longevity. For portable gadgets, micro-OLEDs are a smart choice, as they help you maximize runtime without sacrificing performance. Their energy efficiency makes them suitable for applications demanding continuous operation or lightweight, compact designs that prioritize battery conservation.

Visual Display Quality

Micro-OLED displays deliver exceptional image clarity and vibrant colors, making them ideal for applications that demand high visual fidelity. Their sharp details and rich hues make them perfect for scenarios where visual quality is critical. You’ll find these displays excelling in:

- Augmented reality headsets, providing clear overlays and immersive experiences

- Virtual reality devices, offering lifelike visuals for deep immersion

- Wearable tech like smartwatches, ensuring crisp displays in compact sizes

- Professional cameras and viewfinders, delivering accurate color and sharpness

Thanks to their small size and high pixel density, Micro-OLEDs elevate visual performance in space-constrained devices. They create striking images, making your content look more vibrant, precise, and engaging in nearly any application.

Cost and Production Scalability

The cost and scalability of production play crucial roles in determining how quickly and widely each display technology can be adopted. Micro-Oled displays often require advanced manufacturing processes, such as precise patterning of tiny pixels, which can be more expensive and complex than traditional OLED production. As a result, initial costs tend to be higher, and scaling up production may be slower. Conversely, OLED technology benefits from established manufacturing methods, allowing for easier scale-up and cost reduction over time. When you consider large-scale deployment, these factors influence device pricing and availability. While Micro-Oled displays promise better performance, their higher production costs and limited scalability currently hinder mass-market adoption compared to OLEDs.

Future Developments and Technological Trends

Advancements in display technology are driving rapid innovation, with researchers exploring new materials and manufacturing techniques to enhance performance and reduce costs. Future trends in Micro‑OLED and OLED tech focus on pushing boundaries.

- Quantum Dot Integration – Boosts color accuracy and brightness, making displays more vivid.

- Flexible and Foldable Designs – Allows seamless integration into wearable tech and foldable devices.

- Improved Manufacturing Processes – Reduces costs and enhances scalability for wider adoption.

- Enhanced Durability and Efficiency – Extends lifespan and reduces power consumption, ideal for portable devices.

Frequently Asked Questions

How Does Micro‑Oled Technology Impact Device Weight?

Micro‑oled technology makes devices lighter because it uses smaller, more efficient components. You’ll notice your gadgets become less bulky since micro‑oled screens are thinner and require less power. This reduction in size and weight enhances portability and comfort, especially for wearable tech like smart glasses or headsets. By replacing traditional OLED displays with micro‑oled, you get a sleeker, more lightweight device without sacrificing screen quality or performance.

Can Micro‑Oled Displays Be Used Outdoors Effectively?

You can definitely use micro-OLED displays outdoors effectively. They offer high brightness and contrast, making images clear even in bright sunlight. Their fast response times reduce glare and motion blur, enhancing visibility. Plus, their compact size allows for versatile device design, so you get sharp visuals on small screens or heads-up displays. Overall, micro-OLED displays perform well outside, providing vivid, easily viewable images in various lighting conditions.

What Are the Environmental Concerns With Micro‑Oled Manufacturing?

You might wonder about the environmental concerns with micro-OLED manufacturing. You should consider the energy consumption involved, the use of hazardous chemicals, and waste management challenges. You also need to think about resource extraction, potential pollution, and recycling difficulties. These factors can impact ecosystems, water quality, and energy resources. Being aware of these issues helps you support sustainable practices and push for greener technologies in micro-OLED production.

Are Micro‑Oled Displays More Environmentally Friendly Than OLED?

You might wonder if micro-OLED displays are greener than OLEDs. Generally, micro-OLEDs use fewer materials and consume less power, making them more environmentally friendly. They also tend to have shorter manufacturing processes, which reduces waste and energy use. However, the environmental impact depends on production practices and disposal methods. Overall, micro-OLEDs have potential for a smaller ecological footprint compared to traditional OLEDs.

How Does Micro‑Oled Technology Influence Device Thermal Management?

Think of micro-OLED technology as a cool breeze for your device’s thermal management. It generates less heat because it’s more energy-efficient, so your device stays cooler and runs smoother. With smaller pixels, micro-OLED disperses heat more evenly, preventing hotspots. This means better performance and longer lifespan, like a well-oiled machine. You get a device that stays comfortably cool, even during intense use, thanks to this innovative display tech.

Conclusion

Understanding the dance between micro-OLED and OLED displays reveals a symphony of innovation, where size, clarity, and efficiency play their parts. Micro-OLEDs are the delicate brushstrokes in miniaturized masterpieces, while OLEDs are the broad strokes shaping larger visions. As technology advances, these displays weave a tapestry of possibilities, each thread brighter and more resilient. Embrace this evolution, for it’s the dawn of a luminous future where tiny giants illuminate our world in ways we’ve only begun to imagine.