I’ve researched the top server rack grounding kits for 2026 and found some excellent options I trust for safety and durability. These include kits with copper bus bars, aluminum lugs, and easy-to-install grounding panels. They meet industry standards and work well with standard 19-inch racks. If you want to make sure your setup is safe and reliable, keep exploring these options—there’s more to take into account before making your choice.

Key Takeaways

- Choose grounding kits made from durable, corrosion-resistant materials like copper and aluminum for long-lasting performance.

- Ensure compatibility with standard 19-inch racks and include necessary mounting hardware for easy installation.

- Verify that the grounding kit meets industry safety standards such as NEC, UL, or IEC certifications.

- Opt for kits with comprehensive components like grounding bars, cables, and jumper bridges for effective grounding.

- Consider ease of installation, maintenance, and compatibility to ensure reliable, safe, and compliant server rack grounding.

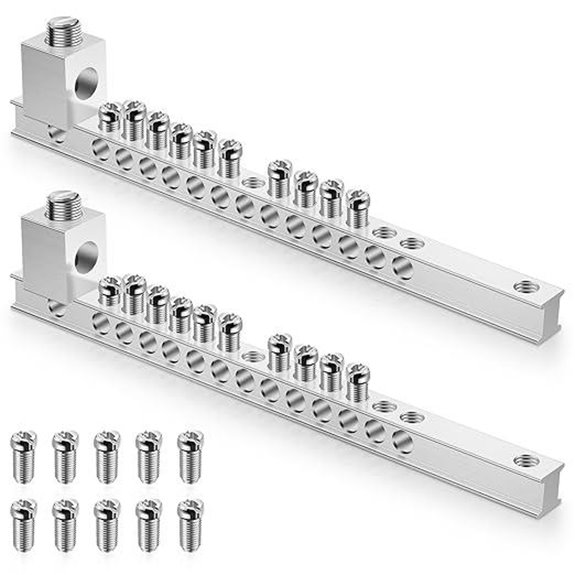

| Ground Bar Kit with 10 Terminals and Lug Bar |  | Reliable Grounding Option | Compatibility: Suitable for distribution boards and complex systems | Material: Aluminum (grounding lugs) | Length/Size: Terminal lugs approx. 0.75 x 0.75 x 0.98 inches | VIEW LATEST PRICE | See Our Full Breakdown |

| 19-Inch Copper Bus Bar Kit with Grounding Cable |  | Heavy-Duty Copper Bar | Compatibility: Designed for 19-inch data racks, cabinets, enclosures | Material: Copper (C110 copper bus bar) | Length/Size: Bus bar length 19 inches; grounding cable 4 ft | VIEW LATEST PRICE | See Our Full Breakdown |

| Tripp Lite 42U Rack Enclosure Grounding Bar |  | Rack-Integrated Grounding | Compatibility: Attaches to 42U rack enclosures and open racks | Material: Copper (bus bar) | Length/Size: Suitable for 42U racks (size of rack) | VIEW LATEST PRICE | See Our Full Breakdown |

| TRIPP LITE Rack Enclosure Grounding Panel 1U |  | Compact ESD Grounding | Compatibility: Mounts in 1U of standard rack enclosures and open frames | Material: Metal (grounding panel, likely steel/aluminum) | Length/Size: Mounts in 1U space | VIEW LATEST PRICE | See Our Full Breakdown |

| Panduit RGRKCBNJY Rack Grounding Kit |  | Professional Rack Solution | Compatibility: Fits 19-inch racks conforming to EIA-310 standards | Material: Metal (rack grounding kit components) | Length/Size: Designed for 19-inch racks | VIEW LATEST PRICE | See Our Full Breakdown |

| MWRF ESD Mat Kit with Wrist Strap and Grounding |  | Static Safety Essential | Compatibility: Used on electronic workspaces, testing and manufacturing areas | Material: Rubber, metal (ESD mat and wrist strap) | Length/Size: Mat size 20″x24″, grounding cord 10 ft | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Ground Bar Kit with 10 Terminals and Lug Bar

If you’re setting up a server rack and need a reliable grounding solution, the Ground Bar Kit with 10 Terminals and Lug Bar is an excellent choice. It includes two complete sets, each with 10 terminals and #4-2/0 aluminum grounding lugs, totaling 20 terminal positions for flexible wiring. The sturdy aluminum lugs are corrosion-resistant with tin plating, ensuring long-lasting conductivity. Installation is straightforward, with all necessary components included, and no special tools required. This kit is versatile, suitable for various electrical systems across residential, commercial, and industrial settings, and meets safety standards for distribution board applications.

- Compatibility:Suitable for distribution boards and complex systems

- Material:Aluminum (grounding lugs)

- Length/Size:Terminal lugs approx. 0.75 x 0.75 x 0.98 inches

- Installation Components:Complete set with terminals and lugs

- Application:Connecting multiple grounding conductors

- Purpose:Electrical grounding, wire management

- Additional Feature:Corrosion-resistant tin plating

- Additional Feature:Complete installation set

- Additional Feature:Suitable for complex systems

19-Inch Copper Bus Bar Kit with Grounding Cable

The 19-inch Copper Bus Bar Kit with Grounding Cable is an excellent choice for anyone looking to guarantee reliable grounding in data racks, cabinets, or enclosures. Made from high-quality C110 copper, it assures durability and effective electrical grounding. The kit includes a sturdy 19-inch copper bus bar, a 4-foot tinned copper grounding cable, and stainless steel screws for secure installation. Its versatile design allows placement anywhere within a 19-inch rack system, making it easy to meet grounding requirements. Whether you’re setting up a new system or upgrading an existing one, this kit offers reliable, straightforward grounding performance.

- Compatibility:Designed for 19-inch data racks, cabinets, enclosures

- Material:Copper (C110 copper bus bar)

- Length/Size:Bus bar length 19 inches; grounding cable 4 ft

- Installation Components:Includes bus bar, grounding cable, screws

- Application:Grounding data racks, cabinets, enclosures

- Purpose:Reliable grounding, effective connection

- Additional Feature:Made from C110 copper

- Additional Feature:4-foot grounding cable included

- Additional Feature:Suitable for data racks

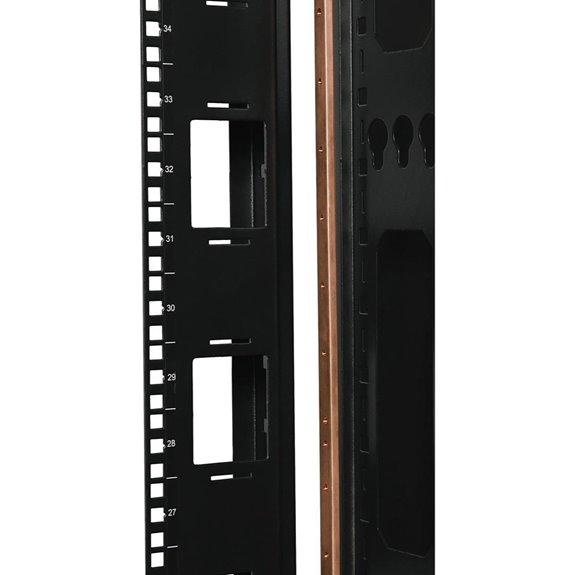

Tripp Lite 42U Rack Enclosure Grounding Bar

The Tripp Lite 42U Rack Enclosure Grounding Bar stands out as an ideal choice for data centers and IT professionals seeking a reliable grounding solution. I appreciate that it attaches securely to both rack enclosure cabinets and open frame racks, with drilled and tapped holes in every U for easy ground wire connections. Its jumper bridges provide direct grounding paths to individual equipment, reducing electrical interference and boosting safety. Plus, it comes with all necessary hardware for quick installation, making setup straightforward. Designed in black for a sleek look, this grounding bar offers a dependable, organized way to protect your server and network equipment.

- Compatibility:Attaches to 42U rack enclosures and open racks

- Material:Copper (bus bar)

- Length/Size:Suitable for 42U racks (size of rack)

- Installation Components:Hardware for attaching to rack

- Application:Grounding server/network enclosures

- Purpose:Equipment grounding, interference reduction

- Additional Feature:Fits 42U enclosures

- Additional Feature:Copper bus construction

- Additional Feature:Ground wire jumpers included

TRIPP LITE Rack Enclosure Grounding Panel 1U

Designed for data centers and server rooms, the TRIPP LITE Rack Enclosure Grounding Panel 1U offers a reliable solution for effective ESD management. This 1U grounding panel mounts easily within standard 19-inch racks and open frame enclosures, providing solid ground contact for banana-plug and alligator-clip ESD bands. It includes 48-inch ground wires for straightforward connections, ensuring quick installation. With a 5-year limited warranty, it’s built to last and compatible with various rack types. Using this panel helps prevent static discharge damage, making it an essential component for maintaining safety and equipment integrity in your server environment.

- Compatibility:Mounts in 1U of standard rack enclosures and open frames

- Material:Metal (grounding panel, likely steel/aluminum)

- Length/Size:Mounts in 1U space

- Installation Components:Mounting hardware and ground wires

- Application:ESD grounding for server racks

- Purpose:ESD safety, static control

- Additional Feature:Mounts in 1U space

- Additional Feature:Compatible with EIA racks

- Additional Feature:Includes 48-inch ground wires

Panduit RGRKCBNJY Rack Grounding Kit

If you’re looking for a reliable grounding solution for your 19-inch racks, the Panduit RGRKCBNJY Rack Grounding Kit offers a straightforward option. It’s designed to maintain network performance and protect equipment, serving as a solid alternative when RGS rack grounding strips aren’t suitable. The kit includes all the matched components you need, making installation quick and cost-effective. The thread-forming screws simplify setup by eliminating the need to remove paint from racks. Built to meet US and international standards, this grounding kit ensures compliance and dependable performance across diverse environments, making it a dependable choice for safeguarding your network infrastructure.

- Compatibility:Fits 19-inch racks conforming to EIA-310 standards

- Material:Metal (rack grounding kit components)

- Length/Size:Designed for 19-inch racks

- Installation Components:Complete kit with screws and components

- Application:Rack grounding and safety

- Purpose:Network safety, grounding system

- Additional Feature:Thread-forming screws

- Additional Feature:US and international standards

- Additional Feature:Easy component matching

MWRF ESD Mat Kit with Wrist Strap and Grounding

For professionals working with sensitive electronic components, the MWRF ESD Mat Kit with Wrist Strap and Grounding offers reliable static discharge protection. It includes a 20×24-inch nitrile rubber mat, a wrist strap, and a 10-foot grounding cord, ensuring effective grounding during assembly or testing. The mat’s surface resistivity of 10^9 to 10^10 ohms provides a static-safe surface, while the wrist strap guarantees personal grounding. This kit is perfect for electronics manufacturing, repair, and testing environments, helping prevent electrostatic damage. Its straightforward setup makes maintaining static control easy, safeguarding your delicate components reliably.

- Compatibility:Used on electronic workspaces, testing and manufacturing areas

- Material:Rubber, metal (ESD mat and wrist strap)

- Length/Size:Mat size 20″x24″, grounding cord 10 ft

- Installation Components:Wrist strap, grounding cord, mat

- Application:Static discharge in electronics workspaces

- Purpose:Static discharge prevention and safety

- Additional Feature:Nitrile rubber surface

- Additional Feature:Static discharge protection

- Additional Feature:Includes grounding cord

Factors to Consider When Choosing a Server Rack Grounding Kit

When selecting a server rack grounding kit, I focus on compatibility with my racks and the durability of materials to guarantee long-term reliability. I also consider how easy it is to install and whether the grounding capacity meets my system’s needs. Finally, I make sure the kit complies with relevant regulations to keep everything safe and up to code.

Compatibility With Racks

Selecting a server rack grounding kit requires careful attention to compatibility with your existing rack setup. First, verify the kit is designed for standard 19-inch racks, which are common in data centers. Check that the mounting hardware and hole spacing fit your rack’s configuration, whether it’s 1U or 42U. The mounting method—such as screws, clips, or jumper connections—should suit your rack’s construction material and design. It’s important to confirm that the grounding components are compatible with the rack’s material, like steel or aluminum, to ensure solid electrical contact. Lastly, confirm that the grounding kit meets industry standards and specifications relevant to your safety and performance needs. Proper compatibility ensures reliable grounding and maximum safety for your equipment.

Material Durability

Durable materials like copper and aluminum are essential for server rack grounding kits because they offer excellent electrical conductivity and resist corrosion over time. Copper is highly conductive and naturally resistant to oxidation, making it a top choice for reliable grounding. Aluminum, while slightly less conductive, is lightweight and cost-effective, especially when treated with surface coatings like tin plating, which further protects against corrosion. The material’s thickness and build quality also matter, as they determine the kit’s ability to withstand physical wear and environmental exposure. Using high-quality, sturdy metals minimizes maintenance and guarantees consistent grounding performance. Ultimately, selecting grounding components made from proven durable materials guarantees long-lasting reliability, safeguarding your equipment and reducing the need for frequent replacements.

Installation Ease

Selecting a server rack grounding kit that’s easy to install can save you time and reduce frustration. I look for kits with clear, step-by-step instructions that make setup straightforward. Kits with pre-installed hardware and user-friendly components help minimize assembly time, so I don’t waste effort figuring out complicated parts. It’s also important to choose products designed with standard mounting configurations compatible with most server racks, ensuring a smooth installation process. I prefer kits that require minimal specialized tools—using common hand tools makes the job quicker and easier. Additionally, a design that allows for simple cable connections and secure attachment points helps reduce complexity, making the entire installation more efficient. Prioritizing ease of installation to a quicker setup and less hassle.

Grounding Capacity

The grounding capacity of a server rack kit is essential because it determines how effectively it can handle electrical faults and static discharge, safeguarding your equipment and personnel. It’s imperative to ensure the kit’s maximum current rating matches or exceeds the total load of your connected devices. The gauge and material of the grounding conductors, like copper or aluminum, directly influence the system’s current-carrying capacity. Proper grounding capacity not only protects your hardware but also helps guarantee compliance with safety standards. Overloading a grounding kit beyond its rated capacity can cause overheating, corrosion, and connection failures, jeopardizing safety and equipment integrity. Consequently, carefully assess your system’s load requirements and select a grounding kit with sufficient capacity to maintain reliable, safe operation.

Regulatory Compliance

Ensuring your server rack grounding kit complies with local electrical codes and standards is essential for safety and legal adherence. I always check that the grounding components meet requirements like NEC, IEC, or UL standards to avoid potential violations. It’s also important to verify that the kit is rated for the voltage and current of your system, ensuring reliable grounding. I look for products that conform to industry safety standards such as ANSI/TIA-607-C or IEEE, which provide added assurance of performance and safety. Certification labels are a quick way to verify compliance, so I prioritize kits with clear markings. Additionally, I consider whether the grounding kit suits my environment—residential, commercial, or industrial—to meet all regulatory mandates effectively.

Cost Effectiveness

Have you considered how the overall cost of a grounding kit impacts its long-term value? I always evaluate whether the kit’s price reflects its quality and durability, ensuring I won’t need frequent replacements. It’s essential that the kit includes all necessary components to avoid additional expenses down the line. Compatibility with my existing infrastructure is another key factor, preventing costly modifications. I also look for bulk or multi-pack deals, especially when deploying across multiple racks, to get better value. Finally, I consider the ongoing costs of maintenance and replacement over the kit’s lifespan. A more expensive, durable kit that minimizes future expenses can save money in the long run, making it a smarter investment overall.

Maintenance Requirements

Regular maintenance is essential to keep your server rack grounding kit functioning safely and reliably. I recommend inspecting grounding connections regularly to ensure they remain secure and corrosion-free. Cleaning contact points from dust, dirt, and oxidation helps maintain optimal conductivity. Periodic testing of grounding resistance verifies that your system continues to meet electrical safety standards. It’s also vital to confirm all components are firmly fastened and undamaged, reducing the risk of grounding failure. Following manufacturer guidelines and industry safety standards for scheduled maintenance will prolong the lifespan of your grounding system and prevent costly issues. Staying proactive with these checks ensures your server rack remains properly grounded, minimizing downtime and safeguarding your equipment. Remember, consistent maintenance is key to long-term safety and reliability.

Frequently Asked Questions

How Often Should Server Rack Grounding Systems Be Inspected?

I recommend inspecting your server rack grounding system at least once every six months. Regular checks help make certain all connections are secure, corrosion is absent, and grounding paths remain effective. If your environment experiences heavy dust, humidity, or temperature fluctuations, more frequent inspections—perhaps quarterly—are advisable. Staying proactive prevents potential issues, maintains safety, and ensures your equipment stays properly grounded, minimizing risks of electrical faults or damage.

Can Grounding Kits Prevent Electrical Noise in Data Centers?

Grounding kits can truly be the knights in shining armor against electrical noise in data centers. They effectively reduce electromagnetic interference and static, ensuring cleaner signals and more reliable equipment performance. By creating a solid electrical ground, these kits help maintain ideal data transmission and prevent costly errors. Trust me, investing in a quality grounding kit might just save you from a tech chaos that’s as chaotic as a hurricane!

Are Grounding Kits Compatible With All Server Rack Sizes?

Grounding kits aren’t universally compatible with all server rack sizes, but most are designed to fit standard configurations. I always check the specifications before purchasing to verify the kit matches my rack’s dimensions and mounting points. If you have a custom or non-standard rack, look for adaptable kits or consider consulting a professional. Proper compatibility ensures effective grounding and protects your equipment from electrical issues.

What Certifications Should I Look for in Grounding Kits?

You should look for grounding kits with certifications like UL, CE, or RoHS. These verify the product meets safety, quality, and environmental standards. I always check for UL certification because it guarantees the product has been tested for safety. CE is essential if you’re in Europe, and RoHS confirms the kit is free from hazardous substances. These certifications give me confidence in the kit’s reliability and safety.

Do Grounding Kits Require Professional Installation?

I believe grounding kits don’t always need professional installation, but it depends. Imagine connecting a sturdy, reliable web that keeps everything safe and stable—if you’re comfortable with basic electrical work, you can usually handle the installation yourself. However, for complex setups or if you’re unsure, hiring a professional ensures everything’s done correctly and safely. It’s better to be cautious than risk improper grounding that could cause issues later.

Conclusion

Choosing the right grounding kit can feel overwhelming, but trust me, it’s essential for safety and performance—like a superhero shield for your equipment. From sturdy bars to thorough grounding sets, there’s a perfect fit for every server rack. Don’t settle for less; your gear deserves the best protection possible. With the right grounding kit, you’ll keep your systems safe and running smoother than a well-oiled machine. Stay protected, stay confident!